Description

Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations. These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high-output to the end user.

Standard Features

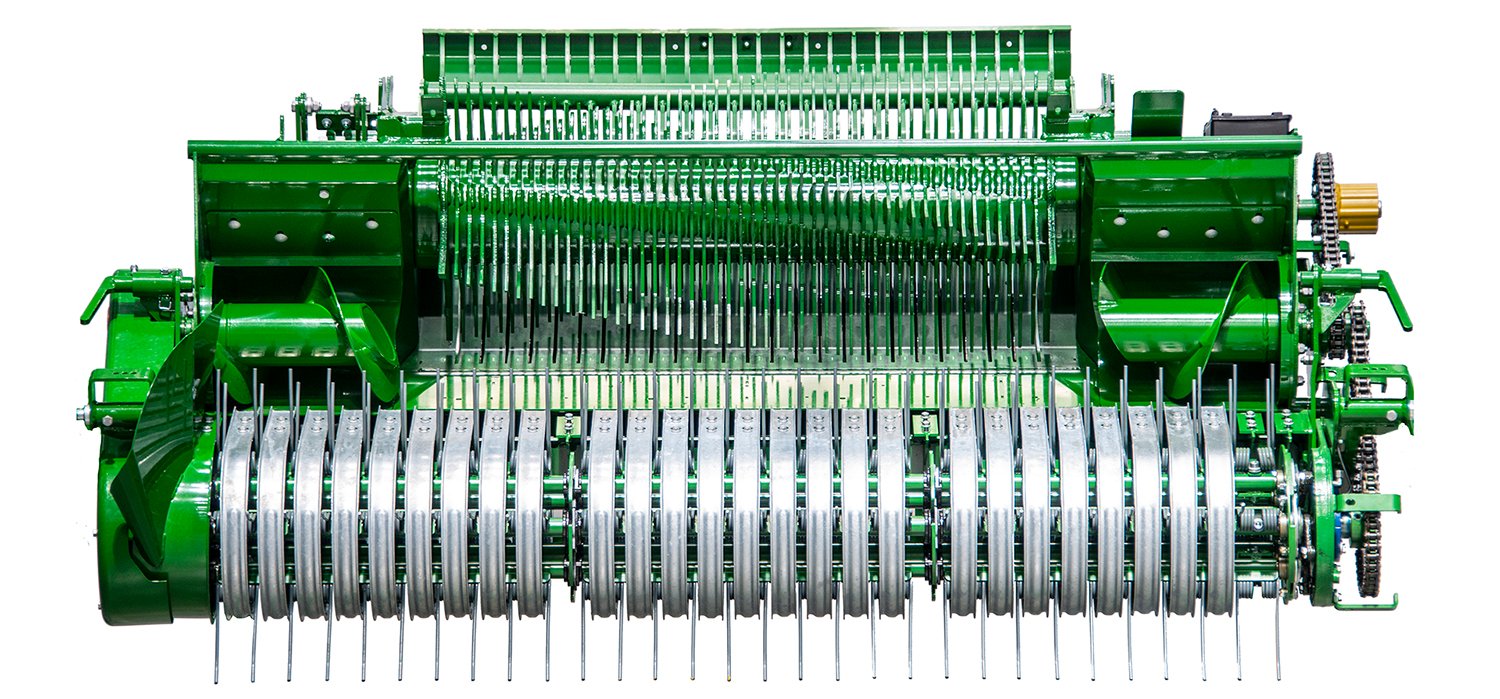

• 2.1 m Profi-Flo Pick-Up

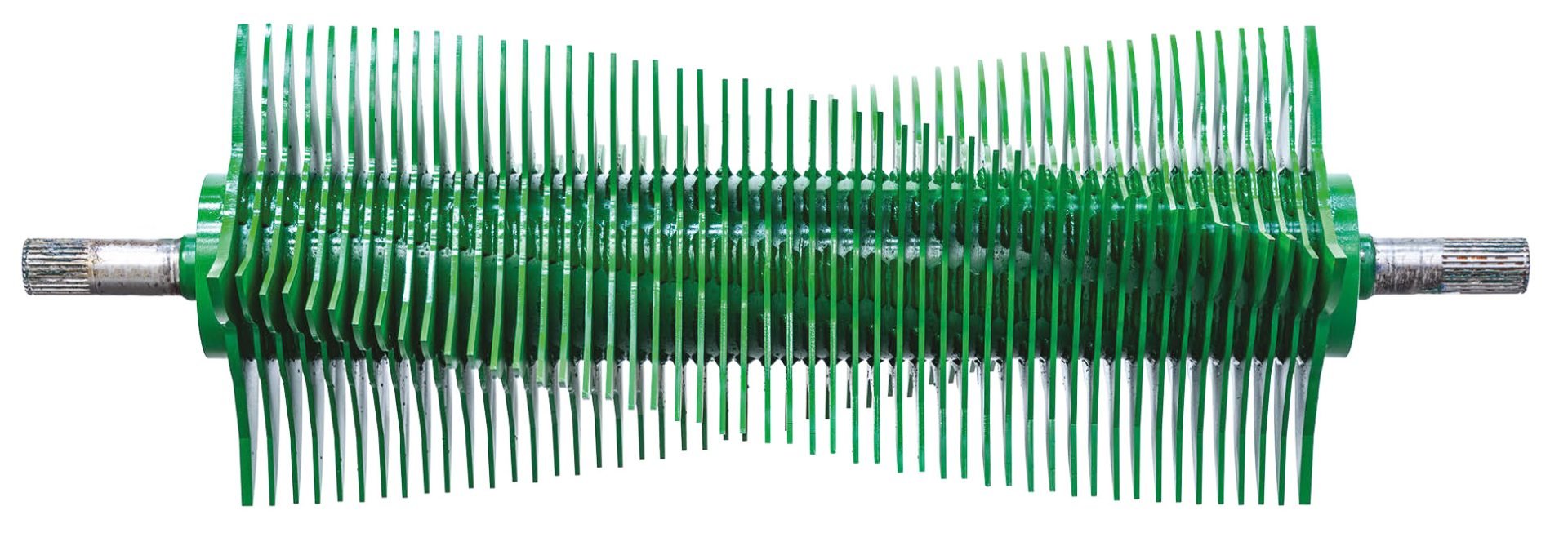

• 25 Knife Heavy Duty Feed Rotor

• Drop Floor Unblocking System

• 18 Roller Bale Chamber

• 50 & 55 mm Bale Chamber Bearings (55 mm bearings fitted to rollers with long shafts and double sprockets)

• 1¼” Chain on the Bale Chamber

• Automatic Progressive Greasing System

• 4 Bar Pivot Stretch Netter

• Automatic Oiling System

• Expert Plus Control Console with Large Graphic Display

• Vertical Wrapping Ring with Film Break Sensors

• 560/60-22.5 Tyres

PATENTED BALE TRANSFER

When the netting process is complete the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

VERTICAL WRAPPING RING

The vertical wrapping ring is fitted with two 750 mm dispensers, which take approximately 18 seconds to apply 4 layers of film and approximately 24 seconds to apply 6 layers of film. This means that the wrapping platform is always waiting for the next bale.

WRAPPING

Once the bale chamber is closed, wrapping will automatically start and baling can resume, delivering maximum output.

CONTROL CONSOLES

The Fusion 4 is equipped with an Expert Plus control console, which features a large graphic display; this allows the operator to monitor the baling process graphically from the control console.